FRAGOLA

Fragola AN 30 Degree Hose End Push-Lite Series 8000

- Availability:

- Ships from Manufacturer

- Shipping:

- Free Over $98 In U.S. 48

- Type:

- 30 Degree Hose End

- Fitting Style:

- Socketless Barb

- Material:

- Aluminum

- Color:

- Black

- Quantity:

- Sold Individually

Description

Fragola AN 30 Degree Hose End Push-Lite Series 8000

Fragola Performance Systems 8000 Series Push-Lite Race Hose Ends feature are a strong, 1-piece, non-swivel design.

Engineered to be used with our 8000 Series General Purpose or 8600/8700 Series Parker Push-Lok Hoses.

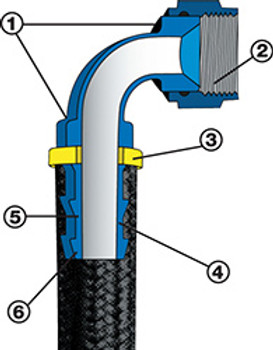

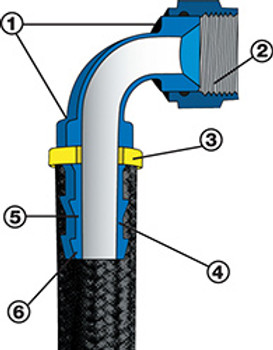

8000 Series Race Hose Ends

1. Unique ONE-PIECE design eliminates two brazed joints, minimizing potential leakage, improving flow and appearance.

2. The correct A-N specified “J-Thread” for ease of installation and trouble-free reuse.

3. Lightweight polymer cap provides positive stop for hose installation, and covers cut end of the hose.

4. Hose barb dimensions per S.A.E. standards.

5. Bright dip anodizing for a show quality finish. All Push-Lite hose ends are manufactured from aerospace-quality aluminum and machined to mil spec tolerances.

6. Tapered nipple for easy alignment and installation.

A-N Threads

Use the profiles below to determine the correct A-N thread before ordering. The corresponding chart displays the outer diameter of the metal tube and thread size.

| A-N Size | Metal Tube O.D. | Thread Size |

| 3 | 3/16″ | 3/8-24 UNJF |

| 4 | 1/4″ | 7/16-20 UNJF |

| 6 | 3/8″ | 9/16-18 UNJF |

| 8 | 1/2″ | 3/4-16 UNJF |

| 10 | 5/8″ | 7/8-14 UNJF |

| 12 | 3/4″ | 1 1/16-12 UNJF |

| 16 | 1″ | 1 5/16-12 UNJF |

| 20 | 1 1/4″ | 1 5/8-12 UNJF |

Torque Specifications

Many people over tighten the aluminum fitting on the adapter, which distorts the 37 degree seat, and may cause leakage. Both the threads and the seat surface should have a drop or two of oil to smooth the tightening process. The maximum torque specifications are listed here. (An alternate method of tightening is to bring the nut to “hand-tight” and then rotate it another turn with the proper wrench.)

| Fitting Size | Max. Torque in Foot Pounds |

| 3 | 8.75 |

| 4 | 11.5 |

| 6 | 16.25 |

| 8 | 29 |

| 10 | 35 |

| 12 | 45 |

| 16 | 70 |

| 20 | 85 |

Size Chart

| A-N Thread | Pipe Thread | B-Nut Hex | ||||

| A-N Size | Tube Diameter | Thread Size (S.A.E.) | Pipe Thread | Threads Per Inch | A-N Size | Hex Diameter |

| -2 | 1/8″ | 5/16-24 | 1/16″ | 27 | ||

| -3 | 3/16″ | 3/8-24 | 1/8″ | 27 | #3 | 1/2″ |

| -4 | 1/4″ | 7/16-20 | 1/4″ | 18 | #4 | 9/16″ |

| -6 | 3/8″ | 9/16-18 | 3/8″ | 18 | #6 | 11/16″ |

| -8 | 1/2″ | 3/4-16 | 1/2″ | 14 | #8 | 7/8″ |

| -10 | 5/8″ | 7/8-14 | 3/4″ | 14 | #10 | 1″ |

| -12 | 3/4″ | 1 1/16-12 | 1″ | 11 | #12 | 1 1/4″ |

| -16 | 1″ | 1 5/16-12 | #16 | 1 1/2″ | ||

| -20 | 1 1/4″ | 1 5/8-12 | #20 | 1 7/8″ | ||

| -24 | 1 1/2″ | 1 7/8-12 | ||||

| -28 | 1 3/4″ | 2 1/4-12 | ||||

| -32 | 2″ | 2 1/2-12 | ||||